1. The long and short line switching mode does not need to replace the clamping device

2. Realize motor electric twisting, and realize two twisting methods of positive and negative. The speed of twisting can be adjusted quickly on the touch screen.

3. Equipped with multi-stage peeling function

4. The front and rear peeling stroke is increased, and the peeling stroke can be made larger;

5. Ultra-wide knife edge is beneficial to protect the core wire, and the ultra-large leaking rubber material port is equipped with a blowing rubber blowing device on the basis of air suction to further ensure that the rubber is collected clean

6. Realize the motor rotation to scrape tin, avoid air pressure interference

7. The heater adopts hot runner device and has a long service life;

8. There are pipeline recovery devices for pine perfume, tin slag, tin ash, etc.

9. It is equipped with a smoke recovery device to keep the machine clean for a long time and maintain a good working environment in the workshop;

10.The machine parts are made of anti-corrosion materials to avoid corrosion; low noise, high precision, high efficiency, long service life, and high cost performance

♣ wire cutting, single-ended double-ended stripping, single-ended double-ended tinning, single-ended double-ended twisted wire, one end double-ended half-stripped, both ends half-stripped

♣Electronic wire, high temperature wire, silicone wire, halogen-free wire, double parallel wire, flat sheathed wire, flat wire, need to be customized according to the wire

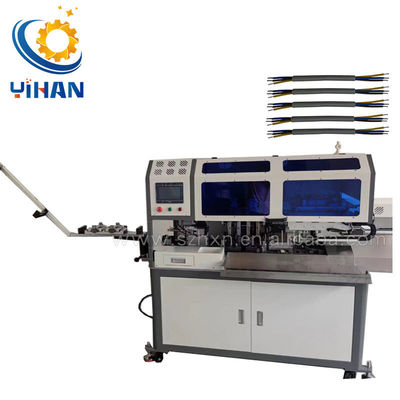

| 1 | Product name | Fully automatic double head Round sheath multi-core wire cutting stripping twisting dipping tinning machine |

| 2 | Chinese and English switching | Provide |

| 3 | Power supply | AC 220V/50/60HZ single phase 1300W |

| 4 | Standard production capacity | 5K-15K(Depend on wire) |

| 7 | Cutting length | 150MM-2000MM (can be customized according to customer requirements) |

| 8 | Stripping length | Outer sheath head:1-50MM Tail:1-150mm Inner core wire head:1-15mm Tail:1-15mm (other sizes can be customized) |

| 9 | Twist length | 3.5-8MM (other sizes can be customized) |

| 10 | Dip tin length | 1MM-8MM(other sizes can be customized) |

| 11 | Air pressure | 0.5-0.7MPA (clean and dry air is required) |

| 12 | Size | Length 4500*width 900*height 1500 (mm) |

| 13 | Wooden box size | Length 5000*width 950*height 1720 (MM) |

| 14 | Weight | About 350kg (gross weight after the wooden box is packed: about 500KG) |

1. Why choose us? Why choose us?

We provide overall solutions for processing equipment. Our standard equipment is very complete, all are in stock and can be shipped quickly. We have our own equipment factory, which can lightly customize equipment according to customer requirements, such as ordering different appearances and brands for agents, and non-standard equipment according to customer requirements.

2. Should I worry about the quality?

Before delivery, we do test the machine working condition for you.

Take a video of the normal operation of the machine to you, and then confirm the delivery

3.How can I know your machine is designed for my product?

You tell us the specific parameters of your product, or you can send us samples of your product and we test it on machine.

Video for you to make samples

4. How to operate the equipment?

My friend, don't worry about it, we have made vedio for you, it will show you how to do it step by step. Contact our engineers at any time when you don’t understand, support video and telephone communication

5.When the machine can't work well,What should I do?

The Engineer is online for 24-hours, they can check the problems and then give you solution way very soon. Please rest assured that manual will be offered along with machine,ensuring you can operate the machine easily.

6.Do your product have warranty and refund or return?

Yes, All our products have one year warranty and no reason refund within 7 days after customer received product(customer need to pay for the Return shipping fee

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!